Learn from the Experts

Free Welder's Handbook!

Pick up your completely free copy of our ‘Welder’s Handbook’ before you go!

The handbook contains a comprehensive guide to gas shielded arc welding and oxy-fuel cutting.

.

Welding is defined as an operation in which two or more parts (metal or plastic) are joined together usually heat, in such a way that there is a continuum between these parts. The continuum. Many materials such as metals and plastics may be welded though some require the use of specific processes and techniques.

The parent material is the material that are to be joined together and the new metal that you will use as part of the welding process to fill the gap between the two pieces of parent metal is called the consumable or filler material because it is consumed in the process and used to fill the gap. It is normal for the filler wire to be the same as the parent material such as mild steel wire for mild steel parent material. This would be a homogeneous weld. If the parent material and the filler material was different then this would be a heterogeneous weld.

Parent Material | Filler Material |

Metal Plastic Pipe | MIG/ MAG Filler Wire (Consumable Electrode TIG Filler Wire |

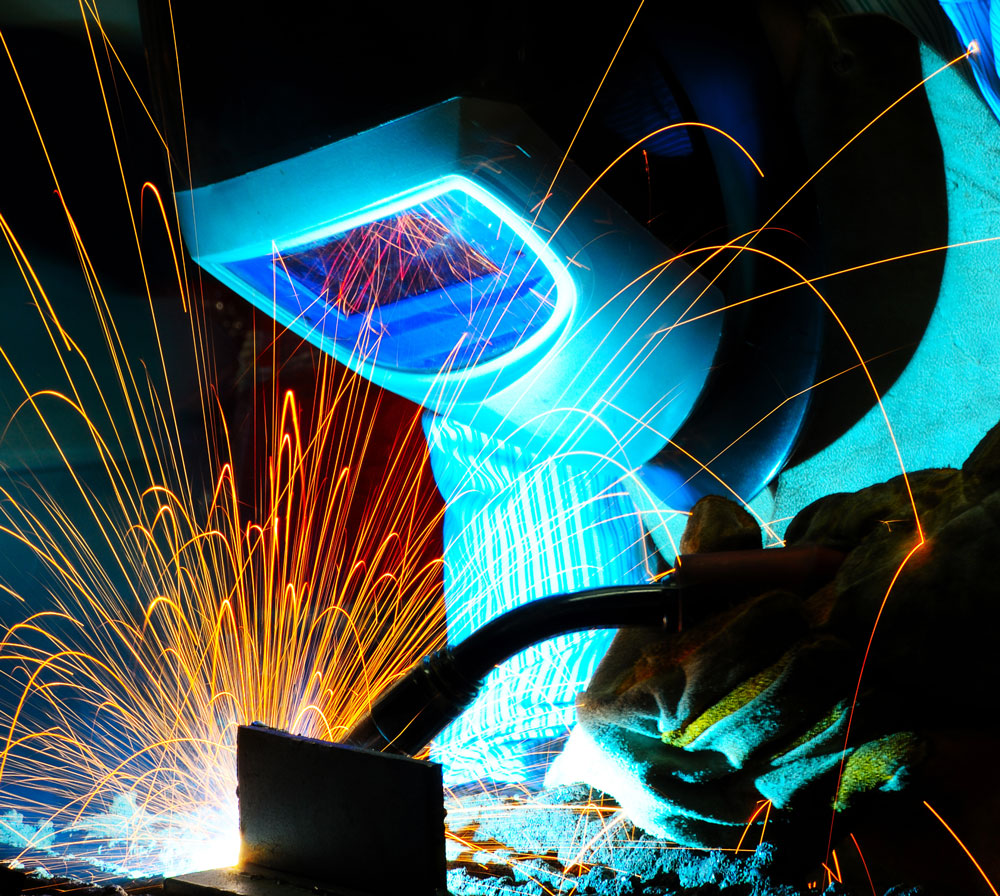

The welding process refers to the type of equipment that you use for welding. There are four main process that we teach at The Welding Academy, there are Manual Metal Arc (MMA), Metal inert/active gas (MIG/MAG), flux-cored arc welding (FCAW), and tungsten inert gas (TIG) are all called fusion or arc welding processes. They are called many different names depending on the industry, slang or country that you are working in. Some common names are described below:

The MIG/MAG welding process is versatile and suitable for thin sheet and thick plate for metals including mild steel, aluminium and stainless steel. The consumables filler wire is the electrode for this process and it will form the arc between it and the parent metal to be welded.

The arc melts the parent material forming the weld pool of parent metal and filler wire that will form the continuum or welded joint. Through the nozzled of the MIG/MAG welding gun gas is fed so that it surrounds the weld pool to protect the weld from oxidation. This gas that protects the weld is called the shielding gas. For mild steel, the filler wire is solid hence the name solid wire and the gas is argon-carbon dioxide mix which has a component that helps the welding process so for steel welding it is a MAG process as the gas is actively involved in the process (Metal Active Gas). For Aluminium the shielding gas is Argon only and is there to shield only so this is a MIG process and the gas is inert to the process Metal Inert Gas.

MMA welding is the most versatile of the welding processes and is suitable for welding mild steel and stainless steel for a large range of thicknesses. The consumable in this process is an electrode which has a core wire with a flux covering. The electrode sits in an electrode holder held by the operator, the arc is formed by striking the electrode across the metal plate, the metal plate and the electrode melt to form a weld pool. The weld pool is protected by the gas formed from the melting of the flux to protect the initial weld pool and then the formation of slag over the cooling weld. The slag is chipped off when cool to reveal the weld bead.

The TIG welding process is a versatile process for sheet, plate and pipe for metals including mild steel, aluminium and stainless steel. The arc and therefore the heat is between tungsten and the parent metal. The tungsten is a non-consumable although you will use a few whilst learning to weld as they need to be sharp during welding. Argon is released from the welding torch to form an inert gas shield around the electrode and weld zone to prevent oxidation.

There are three ways of striking the arc scratch start which is started by scratching the tungsten across the metal plate. Lift-arc which also relies on touching the electrode to the metal as the electrode is withdrawn from the workpiece and the arc starts. The most common method of arc initiation is by using a high frequency (HF) spark. of high voltage, but very low current, HF creates a spark between the electrode and the workpiece that will initiate the welding arc and plasma formation.

Working together on a common platform and working towards the achievement of a common goal

Auxo means to “grow” and we believe that everyone should be provided with the equal opportunity to grow

To enable learners and their wider communities to build a socially-just, sustainable and equitable society

Pick up your completely free copy of our ‘Welder’s Handbook’ before you go!

The handbook contains a comprehensive guide to gas shielded arc welding and oxy-fuel cutting.