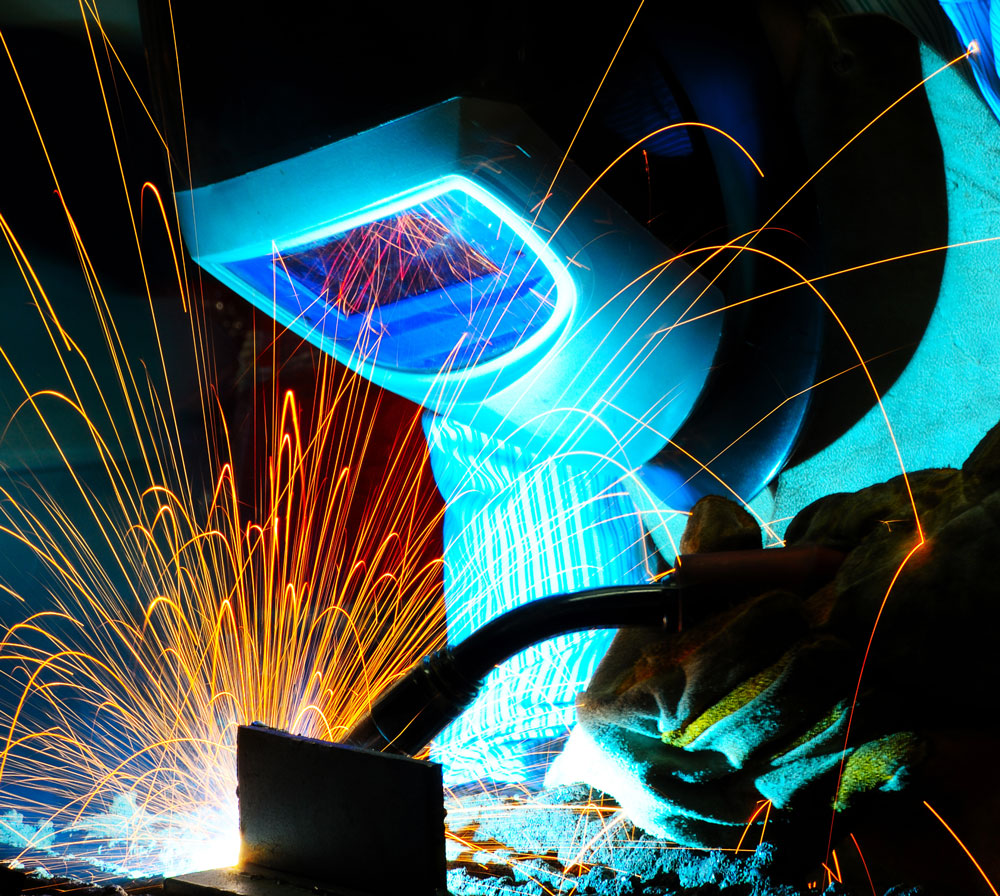

METAL FABRICATOR APPRENTICESHIP

We are a national Apprenticeship provider specialising in STEM training, supporting employers to upskill their workforce in addition to training new staff members.

Working with you, we will build programmes of study that meet the needs of each individual apprentice and employer. Our programmes base equal importance on the knowledge, skills, and behavioural components of welding and fabrication standards, to produce a well-rounded apprentice and competent welder. We deliver apprenticeship training to the engineering, manufacturing, power generation, oil and gas, petrochemical and process sectors.

Occupational Profile for Metal Fabricator Apprenticeship

This occupation is found in the advanced manufacturing engineering and engineering construction sectors.

The broad purpose of the occupation is to carry out metal fabrication work using things such as rolled steel joists, columns, channels, steel plate and metal sheet etc.

Work includes manufacturing bridges, oil rigs, ships, petro-chemical installations, cranes, platforms, aircraft, automotive and machinery parts, sheet metal enclosures, equipment supports, and anything that can be fabricated out of metal. Fabricators can work alone or in teams, in factories or on operational sites.Fabricators use a large range of metals including steel, aluminium and titanium at a range of thicknesses from 0.5mm up to over 20mm. The size and weight of the fabrications can range from components that can easily be picked up by hand, to massive structures that require several cranes to manipulate.

In their daily work, an employee in this occupation interacts with planners, supervisors, inspectors, designers, welders, pipefitters, fitters, machinists, riggers, steel erectors, stores personnel, painters and many others involved in manufacturing, production, maintenance and repair.

An employee in this occupation will be responsible for the quality and accuracy of their own work whilst ensuring it conforms to a relevant specification such as an engineering drawing or an international standard. Fabricators are also responsible for the health, safety and environmental (HS&E) protection of themselves and others around them.

Entry requirements

Individual employers will set the recruitment and selection criteria for their Apprenticeships. In order to optimise success, candidates will typically have 4 GCSEs at Grade C/4 or equivalent, including Mathematics, English and a Science.

Professional Recognition

This standard has professional recognition for Eng Tech through IMechE, IET or Royal Aeronautical Society.

Occupational Duties

Duty 1 Work safely at all times complying with health and safety legislation, regulations, organisational and environmental requirements.

Duty 2 Plan and prepare for the METAL fabrication activities before commencing work.

Duty 3 Check materials conform to the specified grades, dimensions and thicknesses identified on detailed engineering drawings.

Duty 4 Use the correct methods for the moving and handling resources and materials.

Duty 5 Set up, check AND adjust the equipment for use in the safe and reliable fabrication of METAL products or components and maintaining the equipment in a reliable and safe condition throughout.

Duty 6 Interpret technical drawings, patterns, templates and specifications to mark out, produce and assemble complex fabricated products to meet the required specification and quality requirements.

Duty 7 Use appropriate tools, equipment and techniques to shape and form (HOT or COLD) metal materials, demonstrating and applying knowledge of material properties and characteristics throughout..

Duty 8 Monitor resources and activities throughout the fabrication of products or components, identifying areas for improving the production process where possible

Duty 9 Cutting, drilling, shaping and preparing METAL materials during fabrication activities using manual and power tools, thermal and laser cutting, as required calculating dimensions and tolerances using knowledge of mathematics and instruments/equipment

Duty 10 Operate appropriate tools and equipment to join metal parts using a range of mechanical fasteners and fixing techniques required by the specifications appropriate to the fabrication activity being carried out and in accordance with approved joining procedures and quality requirements

Duty 11 Operate thermal joining equipment to join metal parts using a range of appropriate techniques to the standards required by the specifications for the fabrication activity being carried out

Duty 12 Inspect and test joins for security against required standard

Duty 13 Carry out quality checks on component parts and completed assemblies

Duty 14 Deal with problems that occur within the fabrication activity in line with responsibilities of the role

Duty 15 Restore the work area and equipment to a safe and reliable condition on completion of the activity

Duty 16 Complete documentation at the appropriate stages of the work activity

Collaboration

Working together on a common platform and working towards the achievement of a common goal

Growth

Auxo means to “grow” and we believe that everyone should be provided with the equal opportunity to grow

Commitment

To enable learners and their wider communities to build a socially-just, sustainable and equitable society

To complement your practical skills you will complete a recognised academic qualification, which will include basic maths, health and safety, pattern development, drawings and associated welding theory.

English & Maths

Apprentices without level 2 English and maths will need to achieve this level prior to taking the End-Point Assessment. For those with an education, health and care plan or a legacy statement, the apprenticeship’s English and maths minimum requirement is Entry Level 3. A British Sign Language (BSL) qualification is an alternative to the English qualification for those whose primary language is BSL.

Other mandatory qualifications

Diploma in Advanced Manufacturing Engineering (Development Knowledge) or Extended Diploma in Advanced Manufacturing Engineering (Development Knowledge)

When assessed to be competent you will actually be able to fabricate plate work from a drawing and assemble components using welding techniques. These are the technical qualifications that meet the required standards to become a fabrication welder in the industry.

Not sure which course is right for you?

Call 0800 246 14 83

If you’re not sure which course is right please just get in touch and for a no-obligation discussion about the courses.

Our apprenticeship courses

Warning: A non-numeric value encountered in /home/hi2oyhwt/public_html/wp-content/plugins/elementor-pro/modules/woocommerce/classes/products-renderer.php on line 83

Notice: Trying to get property 'taxonomy' of non-object in /home/hi2oyhwt/public_html/wp-content/plugins/elementor-pro/modules/woocommerce/classes/products-renderer.php on line 150