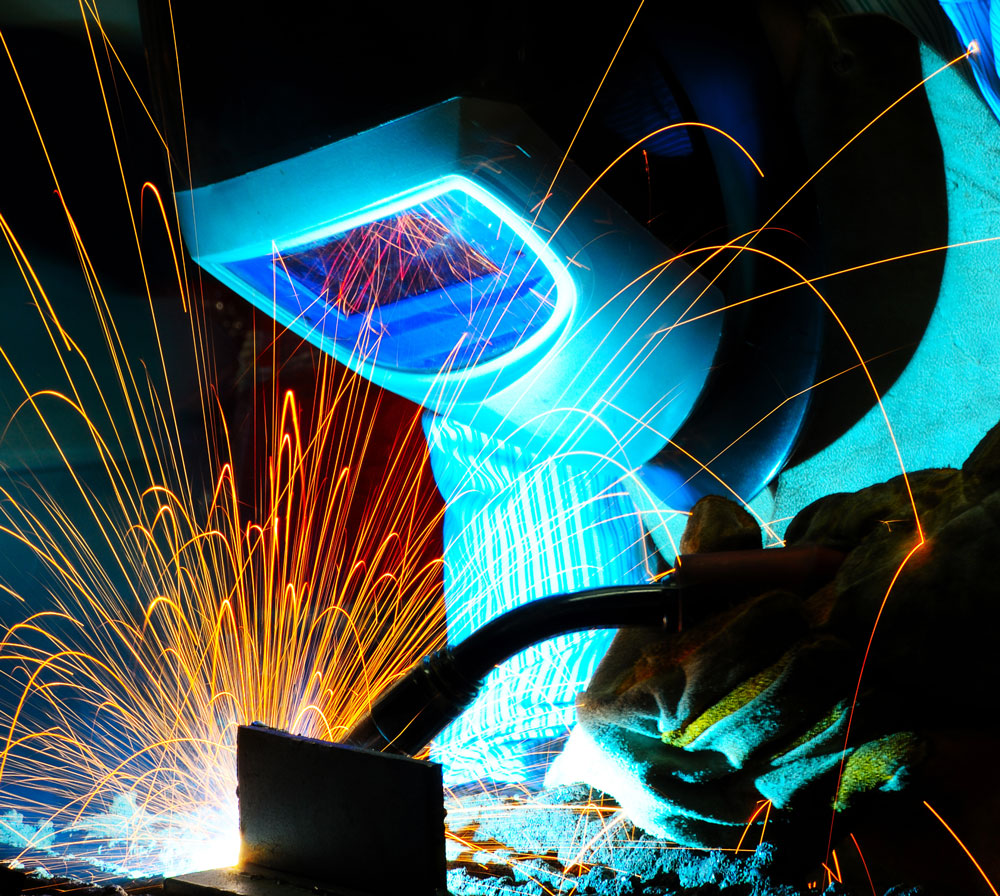

Learn from the Experts

Free Welder's Handbook!

Pick up your completely free copy of our ‘Welder’s Handbook’ before you go!

The handbook contains a comprehensive guide to gas shielded arc welding and oxy-fuel cutting.

We are a national Apprenticeship provider specialising in STEM training, supporting employers to upskill their workforce in addition to training new staff members.

Working with you, we will build programmes of study that meet the needs of each individual apprentice and employer. Our programmes base equal importance on the knowledge, skills, and behavioural components of welding and fabrication standards, to produce a well-rounded apprentice and competent welder. We deliver apprenticeship training to the engineering, manufacturing, power generation, oil and gas, petrochemical and process sectors.

This occupation is found in a wide range of sectors associated with the Fabrication, Construction and upgrade of major capital plant items and facilities. This will include Structural Steel fabrication and construction (e.g. Buildings, Stadia, Bridges, Piers, Jetties etc.), Marine fabrication, construction and upgrade (Ships, Submarines, Wind Turbine Towers), Defence fabrication (armoured vehicles), Process Plant (structures and storage tanks), Engineering Construction (Lifting Beams, Cranes, Construction Vehicles etc.), Mining & Mineral Processing (Shuttering, Structural Supports, Wear Plates, Chutes, Mills, Pulverisers), Transport (Aerospace, Rail and Automotive), and Manufacturing of machinery & equipment. Plate Welders may be employed in any size of organisation from small companies to large multi-national organisations.

Typical job titles include:

Plate welder, Structural welder, Class B welder, Coded multi-positional plate welder

Individual employers will set the recruitment and selection criteria for their Apprenticeships. In order to optimise success, candidates will typically have 4 GCSEs at Grade C/4 or equivalent, including Mathematics, English and a Science.

This standard has professional recognition for Eng Tech through IMechE, IET or Royal Aeronautical Society.

Working together on a common platform and working towards the achievement of a common goal

Auxo means to “grow” and we believe that everyone should be provided with the equal opportunity to grow

To enable learners and their wider communities to build a socially-just, sustainable and equitable society

Duty 1 Plan and prepare for the welding of plate, structural components before commencing work

Duty 2 Check materials conform to the specified grades, dimensions and thicknesses.

Duty 3 Inspect weld preparations, surface conditions and cleanliness

Duty 4 Assemble and position plate and structural components to be welded, including attachment of bracings, strong-backs, alignment aids, run-on and run-off tabs and backing materials (e.g. ceramic, metallic etc.).

Duty 5 Assemble equipment to be used in the preparation and welding of plate and structural components and check its performance and condition, including any component heating and monitoring equipment.

Duty 6 Adjust and maintain the equipment to be used during the welding of plate and structural components.

Duty 7 Interpret technical specifications & drawings to establish detailed welding process controls, consumable selection, and dimensional limitations imposed to control distortion.

Duty 8 Make the joints to specified dimensional accuracy using appropriate welding techniques.

Duty 9 Identifying areas for improving the production process where possible through the monitoring of performance

Duty 10 Monitor associated parameters throughout the welding of plate and structural components (e.g. Preheat, Interpass Temperature, Heat Input).

Duty 11 Remove material using manual powered and non-powered hand tools, before and during welding to remove defects within the preparation and weld deposit.

Duty 12 Visually inspect alignment and distortion of component and apply techniques to ensure compliance with specification.

Duty 13 Visually inspect completed weld and component geometry

Duty 14 Remove and dress bracings, strong‐backs, run-on/run-off tabs and alignment aids, and dress finished external weld surfaces using manual powered and non‐powered hand tools

Duty 15 Restore the work area and equipment to a safe and reliable condition on completion of welding including the remediation and recycling of bracings, strong‐backs and alignment aids.

Duty 16 Monitor the use of consumables and adjust quantities issued, and return unused consumables for re-conditioning, re‐use or disposal.

Duty 17 Complete production documentation and reporting at the appropriate stages of the work activity

English & Maths

Apprentices without level 2 English and maths will need to achieve this level prior to taking the End-Point Assessment. For those with an education, health and care plan or a legacy statement, the apprenticeship’s English and maths minimum requirement is Entry Level 3. A British Sign Language (BSL) qualification is an alternative to the English qualification for those whose primary language is BSL

Pick up your completely free copy of our ‘Welder’s Handbook’ before you go!

The handbook contains a comprehensive guide to gas shielded arc welding and oxy-fuel cutting.